Efficiency and Durability in Sulfur Transport

The client needed to optimize the handling system by reducing delivery times and costs, while increasing the service life of conveyor belts to ensure reliability in a critical production process.

The Problem

The previous belts were not robust enough to withstand demanding operating conditions, leading to frequent replacements and downtime. A stronger, longer-lasting, and more efficient solution was required.

The Solution

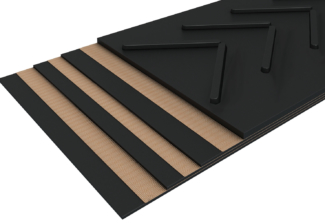

We supplied five Unirigid 400/3 3.5+1.5 B-650 conveyor belts, equipped with reinforced sidewalls, for a vertical 90° “Z” lift system transporting sulfur pellets to a storage silo. Four belts run in parallel, with one kept as a spare.

This solution provided greater robustness, extended service life, and a significant reduction in operating costs.

With the new UNIRIGID belts we have reduced downtime and improved efficiency: a reliable and durable solution.