Efficiency and Innovation in Mixer Wagons

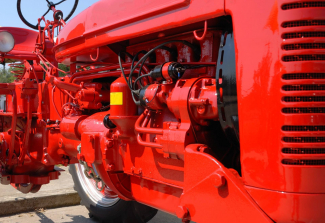

In the agricultural sector, operational efficiency and the durability of mechanical components are essential to ensure productivity and reduce maintenance costs. In this context, our customer, a manufacturer specialized in the production of mixer wagons and straw choppers was facing a critical challenge related to the milling belts used for material collection.

The Problem

The original belt in use was a 400/3 3+0 flat class model, working by sliding and in contact with the rollers. However, due to the narrow layout and limited development of around 8 meters, the customer experienced a significant material shrinkage issue. This phenomenon, which in some cases reached several centimeters, caused severe mechanical damage, including motor shaft breakage. As a result, frequent belt replacements became necessary—an extremely complex operation requiring the disassembly of numerous mechanical components. Especially in field working conditions, this led to high costs and considerable downtime.

The Solution

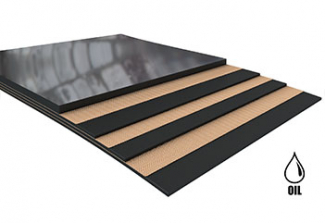

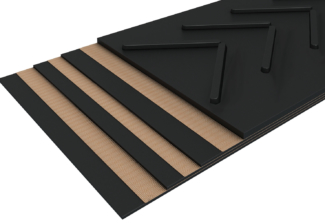

To solve the belt shrinkage issue, an innovative solution was adopted: the use of our UNIOIL belt, a lighter belt with two anti-oil fabric plies, model 250/2 2+1. This change drastically reduced the shrinkage problem, ensuring greater dimensional stability and a significant decrease in mechanical failures. As a result, the customer achieved a substantial reduction in maintenance costs and improved the overall operational reliability of the machine.

Con UNIOIL abbiamo detto addio ai fermi macchina: oggi lavoriamo meglio, più a lungo e senza sprechi di tempo. In campo, ogni minuto conta davvero.