Immediate Stop to Downtime

In industrial recycling, even a minor malfunction can halt production and lead to significant costs. Acting quickly is essential to prevent prolonged downtime and ensure continuous operations.

The problem

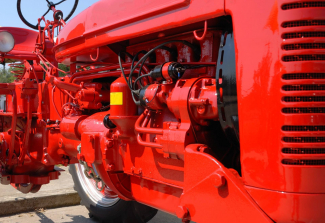

At a waste treatment plant in France, the fall of non-compliant material—heavy and containing sharp metal parts—damaged the lateral guards and compromised the edge of the conveyor belt. An urgent intervention was required to prevent further damage and minimize equipment downtime.

The solution

After a quick assessment, we immediately arranged the shipment of the necessary materials and dispatched two specialized technicians. The intervention was carried out overnight and completed in just three days.

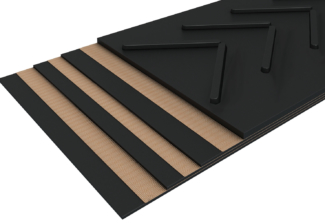

We replaced the belt with our Rubber Conveyor Belt Unioil, highly resistant to oils and aggressive substances. Meanwhile, the on-site team repaired the damaged structural components. This coordinated effort enabled a fast and safe restoration of the system, ensuring full satisfaction for both the customer and the end user.

We were extremely satisfied with the speed and professionalism demonstrated thanks to the Rubber Conveyor belt Unioil. An excellent service that allowed us to resume operations without any issues.