Perfect Alignment: How to Avoid the Risk of Downtime

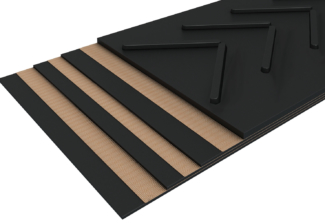

At a major construction site, a conveyor belt over 200 meters long was experiencing severe alignment issues. The risk of plant downtime was high, with inevitable consequences for operational continuity.

The Problem

Due to suboptimal design of the system, the belt continuously drifted off its path, disrupting the consistency of the production flow. The initial proposed solution involved dismantling and rebuilding the entire structure—an intervention that would have been costly both in terms of time and budget.

The Solution

Thanks to our partnership with Flexco—of which we are the exclusive official distributor in Italy—we proposed a quick and effective alternative: a PT Max™ Adjustable Belt Trainer on the carrying side and a PTEZ™ Belt Trainer on the return side. This setup allowed for immediate realignment of the belt, completely eliminating the tracking issue and restoring stability and reliability to the production process—without any structural modifications.

We thought a full overhaul of the system would be necessary. Instead, installing the belt trainers solved the issue quickly and effectively. The belt is now stable, and production is running smoothly.